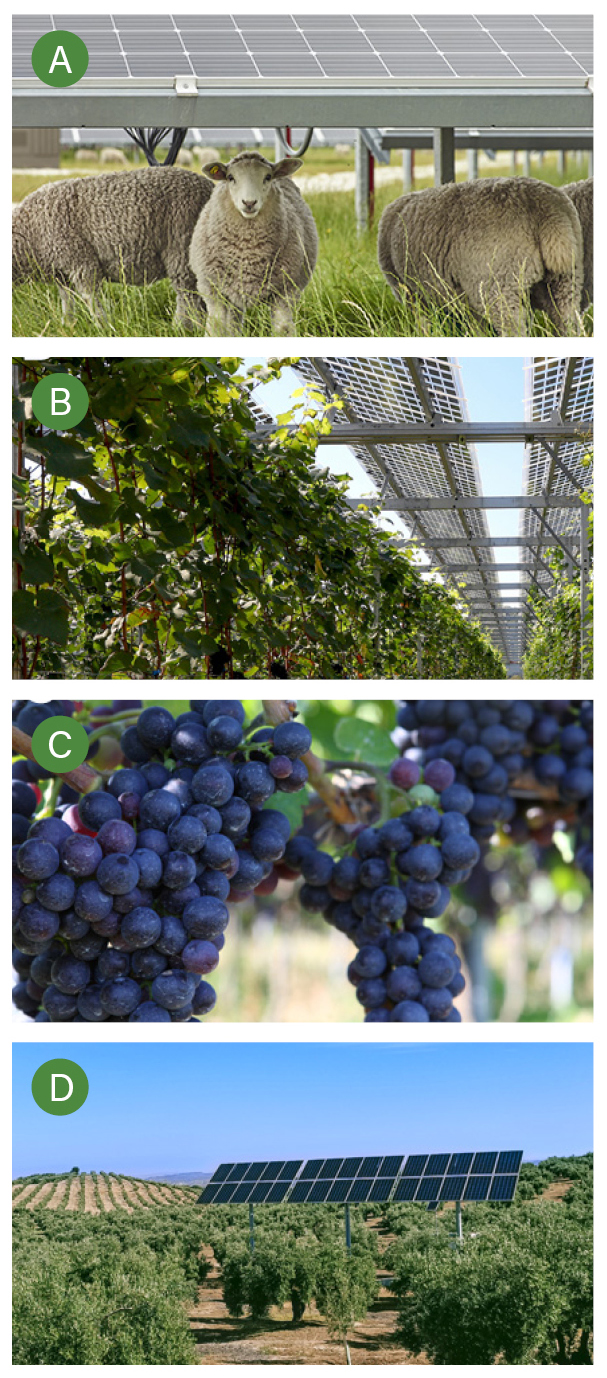

From Texas to New Zealand, flocks of sheep leisurely graze on natural green grasses growing beneath hundreds of rows of solar panels. A

From Texas to New Zealand, flocks of sheep leisurely graze on natural green grasses growing beneath hundreds of rows of solar panels. A

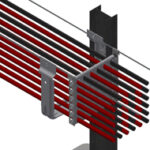

In the Midwest US, researchers have discovered that solar farms can coexist with crops that thrive in partial shade. B

Across the south of France, vineyards are growing grapes for winemaking under the shade and protection of solar panels. C

Spain, famous for its olive oil, integrates solar fields with hedgerow olive tree groves for clean energy generation without disrupting crop production. D

These and other dual land use cases all have one thing in common, actually two: the concept of Agrivoltaics, and the use of Snake Tray’s above ground cable conveyance to carry DC current from the solar arrays to battery energy storage systems and/or AC inverters and out to the power grid.

Well, perhaps not all agrivoltaics installations use Solar Snake Max, the world’s only above ground cable management system that maintains NEC 310.15 compliant cable separation for maximum energy harvest, but in this article, we’ll make the case for why they should. We’ll also discuss how the combination of agrivoltaics and free-air cable management has helped give rise to a new whole industry: solar sheep farming!

Agriculture + Photovoltaics = Agrivoltaics

Agrivoltaics is a model that allows crops and/or livestock to share the land with solar panels (or photovoltaics) rather than compete for it. While clean, renewable energy sources are increasingly desired, a critical issue with solar power is the vast amount of physical space the arrays must occupy to generate sufficient electricity to make the investment profitable.

Many utility-grade solar plants occupy hundreds of acres. In order to maximize land use and value in places such as mountainous New Zealand or the rich soil in the south of France, agrivoltaics is the answer.

The practice involves installing solar arrays over crops that thrive in partial shade, or placing them above rangeland for sheep to graze on the grass growing alongside and under the rows of panels. It slows the loss of habitat and offers natural vegetation control.

The practice involves installing solar arrays over crops that thrive in partial shade, or placing them above rangeland for sheep to graze on the grass growing alongside and under the rows of panels. It slows the loss of habitat and offers natural vegetation control.

This blended land use offers several synergistic advantages for utilities, farmers, and ranchers. Let’s consider our use cases:

Did you know? Snake Tray helped design and manufacture the free-air cable conveyance system for the recently competed 42-megawatt agrivoltaics solar farm in Waiotahe, Bay of Plenty, New Zealand. Read more about it here

What’s in it for Ewe?

-

- Utilities and Sheep Ranchers. Utilities generate clean energy while reducing their carbon footprint and the cost of land maintenance. Using fleets of gas-powered mowers to cut the grass between rows of solar panels is counterintuitive to the whole concept of green energy. Sheep eliminate the cost of labor, fuel and equipment, the production and disposal of clippings, and greenhouse gas emissions from mowing hundreds of acres of grass. Sheep transform what would be environmental waste into a food source. (And their own waste becomes natural fertilizer for next season’s grasses.)The sheep can reach vegetation in small crevices the mowers cannot. They don’t take breaks or vacations and are not impacted by weather or hilly terrain. The shade produced by the panels provides relief for livestock during the heat of the day and slows the evaporation of water from the plants and soil. In addition to reducing watering and irrigation requirements it yields greener grasses longer, which ranchers found positively impacts the tensile strength of sheep wool for a higher quality product.The practice has gained so much traction that it is having a positive side effect on the sheep herding industry. Solar plants the world over are contracting with sheepherders to have their flocks eat the grass. For example, what was once a small side business for a sheepherder has flourished into a full-scale operation called Texas Solar Sheep with more than 8,000 sheep and 26 employees. Utilities get vegetation control with near zero effort, and sheepherders get a cheap food source to lower costs. A win-win!

- Crop Farmers. Researchers have confirmed that solar arrays have no ill effects on crop production and in fact are excellent for plants that thrive in partial shade. They help restore needed ecological habitats for wildlife and pollinating insects. In addition to the shade slowing evaporation and minimizing water use, the panels help regulate air and soil temperature and protect crops from extreme weather effects such as wind, hail and frost, which are intensifying as our planet continues to undergo climate change.

In France, two pilot programs by French agrivoltaics company Sun’Agri reported that not only were the grapes able to grow under solar panels but that the experiment also actually boosted output. The yield of Chardonnay grapes increased by 60%, followed by Marselan at 30% and Grenache Blanc at 20%.

In France, two pilot programs by French agrivoltaics company Sun’Agri reported that not only were the grapes able to grow under solar panels but that the experiment also actually boosted output. The yield of Chardonnay grapes increased by 60%, followed by Marselan at 30% and Grenache Blanc at 20%. In Spain, researchers at the University of Córdoba found solar arrays provided necessary shade and windbreaks for olive trees, minimizing storm damage and increasing crop yields. Agrivoltaics helps curb deforestation while helping to meet Spain’s growing energy needs.

In Spain, researchers at the University of Córdoba found solar arrays provided necessary shade and windbreaks for olive trees, minimizing storm damage and increasing crop yields. Agrivoltaics helps curb deforestation while helping to meet Spain’s growing energy needs. Finally, the solar panels themselves also benefit from agrivoltaics. A part of the photosynthesis process of crops is a process called transpiration, similar to how humans sweat. During transpiration, plants release water vapor from their stomata, or pores, which cool the plant and the surrounding air. This in turn helps solar panels withstand the fierce summer heat that would otherwise limit performance, increasing solar panel efficiency.

Finally, the solar panels themselves also benefit from agrivoltaics. A part of the photosynthesis process of crops is a process called transpiration, similar to how humans sweat. During transpiration, plants release water vapor from their stomata, or pores, which cool the plant and the surrounding air. This in turn helps solar panels withstand the fierce summer heat that would otherwise limit performance, increasing solar panel efficiency.

Solar Snake Max Facilitates Coexistence

Snake Tray’s family of Solar Snake Max products is the key to maximizing agrivoltaics solar farm project ROI whether the use case calls for sheep grazing or crop farming.

Snake Tray’s family of Solar Snake Max products is the key to maximizing agrivoltaics solar farm project ROI whether the use case calls for sheep grazing or crop farming.

The typical agrivoltaics solar farm design features rows upon rows of tracker panels that follow the sun. The modules are attached to piles driven into the ground. The rows are spaced sufficiently apart, and the panels are mounted high above the ground to allow sheep to graze safely and/or crops to grow beneath. The feeder cables from each panel are routed alongside torque tubes or via cable hangers attached to messenger wire suspended under the panels to the end of each row. There, the feeder cables are connected to a combiner box from which the high ampacity DC cables emerge to take over the job of transferring large amounts of current. That’s where old meets new and the Solar Snake Max comes into play.

At this point, engineers have a choice: bury the high ampacity DC cables underground or use free-air cable conveyance to route the cables to their destinations.

Burying cables is a time-consuming, labor-intensive process. Trenching can be messy, delayed by weather and hidden obstacles, and requires expensive earth moving equipment and skilled operators. (Some places, like New Zealand with its volcanic geology and/or low-lying coastal areas where the cables would be buried beneath the water table makes trenching impossible. See our case study). Once the trenches are dug and the cables laid, they must be refilled, and the earth given time to settle.

Burying cables is a time-consuming, labor-intensive process. Trenching can be messy, delayed by weather and hidden obstacles, and requires expensive earth moving equipment and skilled operators. (Some places, like New Zealand with its volcanic geology and/or low-lying coastal areas where the cables would be buried beneath the water table makes trenching impossible. See our case study). Once the trenches are dug and the cables laid, they must be refilled, and the earth given time to settle.

In the case of agrivoltaics, this interrupts or delays mixed land use while the soil and plants recover from disruption to the land. Then there is the issue of derate, meaning utilities will have to overspend on copper conductor materials to offset the effects of energy lost to heat buildup when running cables underground.

Next, consider the long-term maintenance implications of buried cables under an agrivoltaics solar farm: If a cable needs replacement, it must be exposed. That means bringing back earth moving machinery and once again interrupting dual land use. If the installation is in an orchard, such as the Spanish olive groves, over time spreading tree roots will damage DC cables, and pinpointing the failure will be a difficult guessing game.

Or, by using Snake Tray’s exclusive above ground cable conveyance system, agrivoltaics solar farms can reduce labor and material costs while increasing energy harvest. Here’s how:

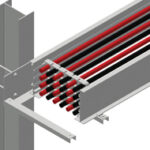

The Solar Snake Max Dual Messenger Wire system carries up to 36 high ampacity DC cables as large as 1250 Kcmil from the combiner boxes at the end of each row of panels to the solar farm inverters. A series of polycarbonate cable separators called “clicks” snap together to hold and maintain NEC 310.15 compliant cable separation distance for up to 6 layers of cables per run. The Solar Snake Max system of brackets and messenger wires attach to ground piles and are positioned high enough to prevent sheep from touching the cables, minimizing disruption to the land – no digging!

The Solar Snake Max Dual Messenger Wire system carries up to 36 high ampacity DC cables as large as 1250 Kcmil from the combiner boxes at the end of each row of panels to the solar farm inverters. A series of polycarbonate cable separators called “clicks” snap together to hold and maintain NEC 310.15 compliant cable separation distance for up to 6 layers of cables per run. The Solar Snake Max system of brackets and messenger wires attach to ground piles and are positioned high enough to prevent sheep from touching the cables, minimizing disruption to the land – no digging!

At some point, the high ampacity DC cables will likely have to move underground, perhaps to traverse a vehicle access road, a sheep crossing, or to connect to a battery energy storage system (BESS). This is where the Solar Snake Max Hard Rail system is used. Galvanized steel hard rails provide the support and framing necessary to change elevations and negotiate short subterranean distances before re-emerging on the other side. Seamless transitions between the messenger wire and hard rail systems are achieved as both systems use Snake Tray’s patented click cable separator mechanism. The underground segments are covered with grated steel plates to continue to allow for free-air cable conveyance without derate, as pictured here.

At some point, the high ampacity DC cables will likely have to move underground, perhaps to traverse a vehicle access road, a sheep crossing, or to connect to a battery energy storage system (BESS). This is where the Solar Snake Max Hard Rail system is used. Galvanized steel hard rails provide the support and framing necessary to change elevations and negotiate short subterranean distances before re-emerging on the other side. Seamless transitions between the messenger wire and hard rail systems are achieved as both systems use Snake Tray’s patented click cable separator mechanism. The underground segments are covered with grated steel plates to continue to allow for free-air cable conveyance without derate, as pictured here.

Benefits of Free-air Cable Conveyance

With Snake Tray, utilities can leverage the concept of agrivoltaics to turn competition and controversy over land use into cooperation and coexistence. The only one of its kind, the trenchless Snake Tray Solar Snake Max delivers these benefits:

-

- Save thousands of hours in labor and earth moving equipment costs by eliminating the need to dig trenches and bury cables. The above ground design traverses any terrain and allows for easier installation, operation and long-term maintenance.

-

- Eliminates billable energy lost to derate. All Solar Snake Max systems maintain NEC 310.15 compliant cable separation for the entire length of a run. This allows the cables to operate more efficiently as heat from electron friction dissipates into the surrounding air. As a result, Solar Snake Max systems yield up to 30-watt hours per meter more than bundled cables for maximum energy harvest and a better ROI.

-

- Save up to 40% in conductive material costs. Solar Snake Max allows for the use of thinner diameter conductive cables to carry 100% of the power load rather than heavier DC cables that lose a sizeable percentage of power to derate when buried or bundled.

- Reduced disruption to the land and simplified maintenance allowing crops or grass to grow and sheep to graze almost immediately after construction. There are never any worries about tree roots interfering with cables. Failure points are easy to spot as the entire cable plant is visible, speeding repairs without pausing dual land use.

Snake Tray: Your Partner for Agrivoltaics

Blended solar/agricultural land use is a trend that is taking hold the world over. Snake Tray solutions bring predictability to unpredictable situations, and in this case, new applications. Solar Snake Max systems install quickly, reduce labor and material costs, significantly drive down the total cost of construction, and maximize energy harvest.

Thinking about your next solar farm coexisting with agricultural crops or livestock? Contact us to learn how Snake Tray facilitates dual land use for renewable energy production and maximum value.