We live in a world full of regulations. From the FDA and the FTC to HIPAA and beyond, there are codes and standards for the production, consumption, and installation of all types of goods and services, and a whole bunch more governing the flow and privacy of information.

Whether the issue is vehicle crash test performance, the warning on consumer products, or requiring food labels clearly state if a product contains peanuts for example, the objective of the code is always to keep people safe. That’s the carrot; the stick is the threat of fines and penalties for compliance violations.

The construction industry is no different. There are countless codes and standards for every aspect of a construction project from electrical wiring practices to the structural integrity of walls and windows built to withstand hurricane force winds. Some come into play well before ground is broken, such as the selection of cost-saving green building materials; others impact the performance after the structure is complete, like smart systems that control climate and electricity usage with maximum efficiency, or fire suppression systems.

This article focuses on the primary codes and standards that apply to Snake Tray’s core products: cable conveyance and power distribution systems.

Cabling Standards Governing Cable Trays

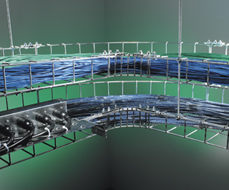

Cable tray capacity, whether hand-bendable wire, rigid basket trays, or heavy duty aluminum or steel ladders, is covered under Article 392 of the NEC (NFPA 70), produced by the National Fire Protection Association.

Article 392 is the bible for indoor cabling standards and is pretty much the only cabling code electricians need to know. It states that for cable trays containing control and/or data cables only (not power), the sum of the cross-sectional areas of all cables at any point shall not exceed 50 percent of the interior cross-sectional area of the cable tray. Further, the tray itself must be suitable for use as an equipment ground conductor, meaning in the event of a fault, the tray will carry voltage harmlessly into the ground and not injure technicians if touched accidentally. Again, safety first.

For example, when running a 4” deep x 12” wide basket tray with 48” square inches of space, the maximum cable capacity of the tray is 24” square inches per foot (4 x 12 = 48 ¸ 2 = 24). The actual number of cables is a function of cable diameter, more for thinner low voltage and fiber optic lines, less for thicker intermediate grade and high amperage cables. Spreading out the cables minimizes the incidence of crosstalk and excessive heat generation from bundling. Therefore, engineers should have a clear idea about the types, volume, and weight of cables that will need to transverse the building in order to select and design a cable management system with the capacity to stay under the 50% full threshold and maintain room for expansion.

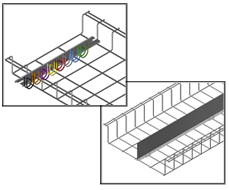

There are also TIA/EIA (Telecommunications Industry Association/Electronic Industries Alliance) cabling standards governing residential and light commercial telecommunications. For example, cables must be color coded to avoid misunderstandings and identify proper wiring patterns for electricians. There are cable tray loading capacity limits to avoid cable crushing, and requirements to separate low voltage data and fiber optic lines from power cables to reduce interference.

In outdoor and solar cabling applications, most electricians look to NEC 110.12 for guidance. But NEC 110.12 simply states that “Electrical equipment shall be installed in a neat and workmanlike manner.” That’s it. That means leaving DC feeder cables sagging between minimal support points exposed to rodents, elements, sharp edges, thermocycling, and vandalism is within code. The truth is that NEC 110.12 is woefully inadequate when it comes to utility-grade solar arrays and meeting this standard will do nothing to protect the investment in renewable energy assets.

Power Distribution Code Compliance

There are multiple codes and pieces of legislation on state and Federal levels that call for the use of building materials and systems designed to minimize energy consumption.

LEED (Leadership in Energy and Environmental Design) is perhaps the most widely used green building rating system in the world. Builders are rewarded for using energy-saving materials and systems. While voluntary, LEED certification results in operational cost savings, a reduced carbon footprint, a healthier environment, and may qualify the project for tax breaks and incentives with local authorities.

ASHRAE Standard 90.1 (American Society of Heating, Refrigerating and Air-conditioning Engineers) defines the minimum energy efficiency requirements for the design and construction of new commercial buildings. Always evolving to keep pace with the latest technologies, the 2019 update for example, included rules that state 50% of all 120 V power receptacles in an office or computer classroom must be automatically de-energized when the building, room, or cubicle is unoccupied.

Today, most states have building codes that meet or exceed ASHRAE Standard 90.1, and most government buildings must conform to this standard as well.

One prominent example is California Title 24, and many states have used it as a blueprint for their own energy conservation legislation. California Title 24 covers everything from insulation and roofing materials to HVAC systems, windows, doors, lighting, and power. When it comes to electrical power conservation, Title 24 calls for the use of occupancy sensors and switched circuits that disable non-essential electrical loads when rooms and equipment are not in use. Fines and penalties can be imposed for non-compliance.

Snake Tray Products Help Meet Cabling Standards and Power Distribution Code Compliance

Snake Tray invented the concept of the hand bendable cable try and reinvented the rigid wire basket tray. Our complete catalog of under floor, wall, ceiling, and rack-mountable cable conveyance systems are available in a wide range of sizes and cable capacities to meet NEC Article 392 fill standards for every job. A number of accessories such as pathway dividers and color-coded cable separators to easily adhere to TIA/EIA compliance standards.

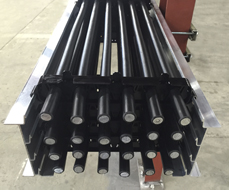

When it comes to outdoor cabling for solar arrays of any size, Snake Tray has solutions that far exceed NEC 110.12. The 407 Series Solar Snake Maxorganizes and protects DC feeder cables on rooftop solar arrays. Its patented lobster trap design makes for easy loading, provides constant support, secures cables out of reach, and is rated to withstand hurricane force winds.

Utility-grade solar plants can manage code compliant separation of high ampacity DC cables with the Solar Snake Max. This unique free-air cable conveyance system increases harvested power efficiencies up to 8%, all day, every day – without trenching or the need to derate cables.

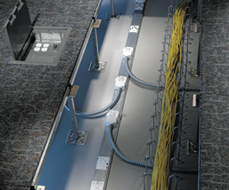

For code complaint power distribution and energy conservation, Snake Tray offers a choice of two revolutionary multi-phase bus bar systems that can de-energize rooms and non-essential equipment as needed for ASHRAE and Title 24 compliance.

The three phase 707 Series Snake Bus and two-phase 717 Series Snake Bus communicate with smart building management systems (BMS) to ensure devices like fans, heaters, calculators, lights, radios, and phone chargers plugged into receptacles designated non-essential are automatically turned off either through occupancy sensors or a timed schedule, while leaving essential equipment powered on.

In addition to helping qualify for LEED certification, Snake Bus experiences less voltage drops, uses less copper for a more efficient solution, and can be moved and reused as needed with minimal labor.

Snake Tray solutions for cable management and power distribution not only exceed published codes and standards, but they will also lower your expenses and improve your ROI.

Let us help design your next project for maximum performance, safety, profitability, and always with an eye on compliance. Contact us at snaketray.com.