When you know exactly what you’re making you can build it faster. When you design a product for repeatability you can make it cheaper. When you make it easy to install you lessen skilled labor requirements, installation time, and costs.

Predictability Yields Construction Efficiency and Savings

When it comes to the cable management of a new or renovation construction project – and what project doesn’t incorporate cables these days? – Snake Tray brings predictability to get the project done faster and with less manpower to lower overall costs and speed job completion. Here’s how:

Hand-bendable Cable Trays

Snake Tray’s patented family of hand-bendable cable trays allow installers to create turns and elevation changes in just 10 seconds compared to 20 minutes for a competitor’s wire basket tray. There are no tools, no cutting, no sharp edges, no waste, no labor burn – just bend them into position to navigate around any obstacle. (Figure 1: 101 Series Snake Tray easily navigates the hills and valleys of under floor environments and stands on built-in mounting foot rings.)

Every tray provides the end-to-end support required for today’s delicate fiber optic, low voltage, voice, and data cables – eliminating the sagging and stress associated with using J-hooks while maintaining the proper bend radius for all types of cables. Built-in mounting rings eliminate the need for specialized parts and trapezes, reduces cost, and speeds installation with versatile trays optimized for wall, floor, or ceiling mounting. Tray sections connect in just 15 seconds using a single bolt that creates a physical and grounded bond. Bottom line: Snake Tray products require less labor to install in less time. (Figure 2: 201 Series Snake Tray suspends from threaded rod to traverse long distances, attaches to ceiling beams, or mounts to floor pedestals.)

Snake Tray hand-bendable cable trays are available in a variety of pocket sizes and are excellent for any type of indoor cable conveyance application, but are especially valuable in retrofit and upgrade projects adding modern technology to structures where no cable pathways existed previously.

Hybrid Wire Mesh Cable Trays

Designed to match the strength and capacity of aluminum ladders but at a “basket tray” price point, Snake Tray’s line of pre-manufactured wire mesh cable trays bring predictability to environments with higher cable capacities and heavier loads.

Data centers, manufacturing plants, banks, security/network operation centers and other environments need to manage and maintain visibility to large volumes of low voltage and high voltage cables. Snake Tray’s pre-manufactured wire mesh cable trays allow installers to complete jobs faster and reduce installation costs by skipping the labor-intensive steps of on-site fabrication of fittings and extra parts required by all other cable tray systems.

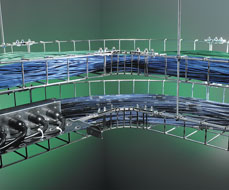

For overhead and rack-mounted cable conveyance, the 801 Series Mega Snake offers prefabricated turns, Tees, and crosses that eliminate hours of cutting, grinding, and assembly while maintaining a consistent cable bend radius. Its built-in suspension system requires only threaded rods to hang from any point – no struts or brackets required – and tray sections securely connect to each other in under one minute with a splice kit that maintains a continuous UL electrical bond. (Figure 6: 801 Series Mega Snake offers pre-manufactured turns, Tees, and crosses to eliminate on-site fabrication.)

To run cables underneath raised access floors, the universal 301 Series Snake Canyon cuts labor costs in half. Simply lift a floor tile and drop in a section to create a totally concealed, protected, yet accessible cable pathway safely separated from other utilities. The trays integrate with any type of 2’ x 2’ floor grid including stringeless floors and require no special tools, accessories, or installation techniques. The trays can be moved and reconfigured as needed while maintaining proper airflow under the floor. (Figure 7: 301 Series Snake Canyon brings cable plant to the surface for easy access.)

Appearances matter

In addition to physical support there is also a psychological aspect to cable management. Factories, data centers, hospitals, schools, and the like don’t instill a lot of confidence in potential customers, patients, and students when cables are disorganized and hanging in a tangled mess. A customer looking to lease space in a data center co-location facility, for example, wants to see the cable plant neatly arranged and supported with proper bend radii maintained, providing the impression of a well-run facility. Snake Tray brings organization and ergonomics to cable management. Trays are available in a galvanized, stainless steel, or powder coated finish. Choose any color to make trays blend in or make an architectural statement should they be installed in an open ceiling concept.

In addition to physical support there is also a psychological aspect to cable management. Factories, data centers, hospitals, schools, and the like don’t instill a lot of confidence in potential customers, patients, and students when cables are disorganized and hanging in a tangled mess. A customer looking to lease space in a data center co-location facility, for example, wants to see the cable plant neatly arranged and supported with proper bend radii maintained, providing the impression of a well-run facility. Snake Tray brings organization and ergonomics to cable management. Trays are available in a galvanized, stainless steel, or powder coated finish. Choose any color to make trays blend in or make an architectural statement should they be installed in an open ceiling concept.

Common Denominators

Whichever Snake Tray solution turns out to be the right one for your next project – hand-bendable or pre-manufactured wire mesh cable trays – electrical contractors save time and labor costs by eliminating the need for on-site fabrication and the resulting waste. All Snake Tray products are manufactured from domestically sourced 100% recycled steel and are made in the USA, eliminating international shipping and supply chain headaches. Further, most Snake Tray products are designed to nest together using a minimum of packaging materials for lower freight costs and easier product handling on site. Less packaging materials also means lighter truckloads, less fuel consumption, and less waste going into landfills for a reduced carbon footprint.

Whichever Snake Tray solution turns out to be the right one for your next project – hand-bendable or pre-manufactured wire mesh cable trays – electrical contractors save time and labor costs by eliminating the need for on-site fabrication and the resulting waste. All Snake Tray products are manufactured from domestically sourced 100% recycled steel and are made in the USA, eliminating international shipping and supply chain headaches. Further, most Snake Tray products are designed to nest together using a minimum of packaging materials for lower freight costs and easier product handling on site. Less packaging materials also means lighter truckloads, less fuel consumption, and less waste going into landfills for a reduced carbon footprint.

Boost construction efficiencies with the predictability of Snake Tray to make cable conveyance systems faster, easier, and cheaper to install. Visit us at www.snaketray.com to learn more and talk to one of our engineers about designing custom solutions to save time and eliminate waste on your next project.