Introduction

As data volumes continue to grow exponentially and network infrastructures become more complex, enterprise data centers and cloud service providers need to keep pace with demand. Some of that is accomplished through upgrading existing on-premises facilities, but the vast majority of businesses are outsourcing at least some of their data management needs to third party providers like Amazon Web Services (AWS), Google Cloud, and Multi-tenant Data Centers (MTDC) or colocation facilities that host multiple enterprise-class clients.

As a result, we are seeing massive growth in data center construction, and with it, some fundamental changes in how data centers are designed and the processes used to build them. Snake Tray pre-fabricated data center cable trays and power distribution systems are the choice of data center architects and engineers seeking to speed deployment and reduce expenses with repeatable, reliable, cost-effective solutions.

The Growth of Data Centers

Data centers are evolving—and multiplying—faster than ever before. That’s because we are generating more data than ever before, and there’s no end in sight. Data has become like a digital currency and, like a bank, institutions that handle greater volumes of it stand to gain the most. Unlike banks, however, data centers are dealing with much more varied data streams than just ecommerce and financial transactions. There are high definition multimedia streaming and downloading, interactive gaming, real-time video conferencing and telemedicine, plus everyday logistics, inventory tracking, and scheduling applications to name a few. New technologies like artificial intelligence, machine learning, and next-generation 5G wireless networks will produce and consume even more data, occupy more storage space, and require faster response. Think autonomous vehicles, flying package delivery drones, and 3D holographic images. Plus, there are more endpoints than ever before; most every consumer has at least one smart device. That means more simultaneous web surfing and ecommerce transactions, more downloads, more social media posts and tags. Factor in the Internet of Things (IoT) where every device gets its own IP address, the lower latency required by 5G, and a blanket security fabric that must be layered over entire network infrastructures, and you’ve got the perfect storm for data center growth.

The current situation is untenable. The networks of tomorrow simply cannot be supported by the infrastructures of today. More data centers are needed to handle the impending tsunami of data. They’re coming, along with hundreds of miles of low and high voltage cables needed to enable the high speed transmission of data and power.

Related Article:

Snake Tray Helps Data Centers Rise to the AI Power Challenge

Types of Data Centers

There are basically two types of data centers, private and public. While they all perform the same functions, there are differences in how they are managed.

Private data centers

These are data management infrastructures owned and operated by a business serving its own organization. Many large enterprises such as automotive manufacturers, airlines, financial institutions, utilities, cable TV providers, national retailers, software giants—really most any Fortune 1000 company—continue to manage their own on-premises data center operations despite the growing burden. This may be for security, control, or competitive reasons, or perhaps their legacy systems and processes are so unwieldy and proprietary that they cannot be transferred. They will procure access to public cloud services through Google, Microsoft, or Amazon, for example, and run the interconnection through their own environment for services they do not offer internally.

Public data centers

These are third party cloud service providers that host data management and internet connectivity services and hardware on behalf of other businesses. Some are very large and well known, like Amazon Web Services, IBM Watson, Oracle, Microsoft Azure, and the Google Cloud Platform. They may be handling the entire data center operations of larger wholesale customers like Netflix, the Weather Channel, or the NFL. There is also a growing segment of “Tier 2” colocation data center providers, or Multi-tenant Data Centers (MTDC). Companies like CoreSite, Equinix, Digital Realty Trust and others have stepped in to provide outsourced data center services to multiple smaller companies under one roof. These retail customers share the expenses for land, power, connectivity, and cooling. For businesses that cannot or no longer want to handle those responsibilities internally, MTDCs can eliminate the headaches of maintaining a private data center. Simply lease secure server/rack cage space and computing hardware, and access scalable web services from the MTDC operator—including direct connections to all major clouds with a single point of contact—for a low monthly fee.

Whether privately or publicly owned, one trend with regard to data centers is the physical placement of facilities closer to end users for improved performance, aka the Edge. Even though data travels at the speed of light, it still takes time for a server on the other side of the country to respond to a request. That won’t do in today’s immediate gratification society. To compensate, cloud service providers are building networks of data centers physically closer to end users to improve response. Moving to the Edge doesn’t necessarily mean “micro” data centers either. Some are pretty big, called hyperscale data centers, and some are large colocation facilities hosting cloud services for dozens of local companies. The Edge is fueling the growth of Multi-tenant Data Center construction, especially for mid-size multi-market businesses.

Today, many companies employ a hybrid data center strategy of keeping some mission-critical systems on-premises for enhanced security and reduced latency, while moving some lower priority IT functions and long-term data storage to a colocation facility. It makes a lot of sense for cost control, disaster recovery, and to support the Edge computing model. At the end of the day, it all adds up to more data center cabling, and with it, the need for cost effective, repeatable cable management solutions.

Related Article:

Snake Tray Addresses Changes Affecting Data Center Construction

Data Center Cable Placement & Standards

Twenty-plus years ago it was common practice to run most if not all data center cabling under raised access floors. This open space made it easy to separate and route cables exactly where needed with few obstructions, and kept cables out of sight. The predominant cooling method at the time was to flood the entire subfloor with chilled air. Diffusers strategically placed underneath cabinet rows would force cold air upwards to dissipate the heat generated by the racks of servers above.

However, the growing volumes of hardware and cables in hyperscale data centers began to impede subfloor air flow, and the cables themselves generate heat. As power and cooling costs increased, engineers began using underfloor ductwork to pump chilled air only where needed. This reduced operating expenses, but also further restricted access to unobstructed subfloor space. As a result, most cable conveyance has since moved overhead, making tray capacity, installation costs, and even aesthetics a part of data center cable tray design consideration.

In smaller data centers where equipment is not expected to be moved or expanded, cable trays are often mounted directly to the top of server racks (TOR). Fewer cables mean less weight, which can be supported by the cabinet frames (Fig. 1). This is usually a faster, easier install requiring less hardware. Lightweight metal basket trays are used for low voltage and fiber optic data cables, and heavy-duty aluminum or steel ladders are used to keep thicker, heavier high voltage power lines separate.

cables mean less weight, which can be supported by the cabinet frames (Fig. 1). This is usually a faster, easier install requiring less hardware. Lightweight metal basket trays are used for low voltage and fiber optic data cables, and heavy-duty aluminum or steel ladders are used to keep thicker, heavier high voltage power lines separate.

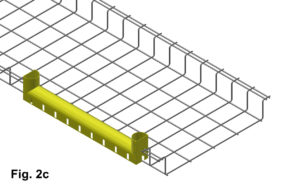

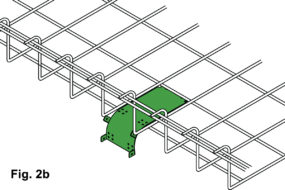

Hyperscale data centers tend to suspend cable pathways from the ceiling using trapeze struts or threaded rods (Fig. 2a). The data center cabling structure itself is massive, extremely heavy when loaded to capacity, and the cable runs are longer. Suspension eliminates the stress of mounting large volumes of cables and trays to server cabinets, and allows for easier rack movement or row expansion without affecting the cable conveyance above. Cable drop-offs positioned above each cabinet safely bend and waterfall cables to their connection points (Fig. 2b). Suspended cable conveyance systems also allow for multiple tiers for easy expansion or to segregate high and low voltage cables (Fig. 2c).

Hyperscale data centers tend to suspend cable pathways from the ceiling using trapeze struts or threaded rods (Fig. 2a). The data center cabling structure itself is massive, extremely heavy when loaded to capacity, and the cable runs are longer. Suspension eliminates the stress of mounting large volumes of cables and trays to server cabinets, and allows for easier rack movement or row expansion without affecting the cable conveyance above. Cable drop-offs positioned above each cabinet safely bend and waterfall cables to their connection points (Fig. 2b). Suspended cable conveyance systems also allow for multiple tiers for easy expansion or to segregate high and low voltage cables (Fig. 2c).

The move to overhead conveyance has given rise to cable tray capacity standards. Whereas an almost unlimited number of cables could be splayed across an open subfloor to minimize alien crosstalk and allow for heat dissipation, organizing cables in a fixed tray limits capacity.

Complying with building codes and industry standards is a necessary part of data center construction, and this applies to cable tray system design and implementation as well. While the most cost and labor efficient method to cable a data center is the use of a prefabricated cable tray management system, you can’t just drop as many cables as you’d like into a run. There are specific rules that must be followed for tray fill capacities.

Cable tray standards are covered under Article 392 of the National Electrical Code (NFPA 70), produced by the National Fire Protection Association. It states that for cable trays containing control and/or signal cables only (not power), the sum of the area of all cables at any cross section shall not exceed 50 percent of the interior cross-sectional area of the cable tray. As an example, a 4-inch-deep, 24-inch-wide tray offers 96 square inches of cable pathway. Assuming the code requires a 50-percent fill rate as its maximum, only 48 square inches of cable can be installed. While voids between cables will be naturally present due to the fact that the cables are round and not square, NEC Article 392 ensures there will be sufficient air gaps between each cable to prevent crosstalk and allow for heat dissipation. Another standard endorsed by the Telecommunications Industry Association (TIA) is even stricter, limiting cable tray capacity to 40%. Therefore, the maximum number of cables allowed within the cable tray – and what qualifies as a “100% full” cable tray – is ultimately dictated by building standards and not the manufacturer or actual physical volume of the tray.

There are also changes in the types of low voltage lines being run inside the data center. Copper is being phased out in favor of multi-strand fiber optic cables that can support faster data transmission speeds. While lighter and thinner, there are more lines, strands, and thus more connections (Fig. 3). Fiber is also more delicate and requires strict adherence to turn radii and elevation change recommendations to maintain optimal performance.

Finally, think about aesthetics. There is tremendous competition among MTDC operators for colocation tenants. In addition tooffering best-in-class performance, looks are also important. When a prospect tours a facility, the building has to be clean, well lit, and properly air conditioned. Open cage doors and dangling cables leave a poor first impression. Prefabricated cable management systems finished to match the décor of the facility go a long way towards presenting and selling the multi-tenant data center as an organized, well-run business (Fig. 4).

Related Article:

Data Center Cabling Best Practices

Data centers are popping up along the fringes of major population areas to bring low-latency services closer to end users for improved performance. In order to speed construction and control costs, architects are standardizing data center design as much as possible. As such, the builders and owners of these properties seek structured data center cabling solutions that offer:

- Repeatability for speed of design and accuracy in cost estimating.

- Easy installation to reduce labor costs and accelerate construction.

- Reliable performance without overpaying.

There are many aspects of data center construction that can be viewed through the lens repeatability/affordability, ease of installation, and reliability. Let’s focus on a few data center cabling best practices that pertain to cable management in a hyperscale data center:

- Never exceed the 50% cable tray fill ratio as per Article 392 of the National Electrical Code.

- Use 18” wide/4” deep trays at a minimum, and preferably 24” wide/4” deep trays whenever possible to account for future expansion. 12” wide/2” deep trays should only be used for micro data centers and IT closets with limited space.

- Design cable pathways with the assumption they will be carrying 100% fiber upon installation or in the near future. Fiber supports the 400G connection speed required for applications like AI and ML, and 5G wireless networks.

- Suspend the cable conveyance from the ceiling whenever possible rather than a Top of Rack (ToR) mount. This makes it easier to move, add, or relocate cabinets as needed without disrupting the pathway.

- Use pre-manufactured turns to maintain proper cable bend radii, especially when running fiber optic. This will save on labor costs and eliminate sharp edges that could damage cables. [Did you know: Many existing data centers, especially co-location sites, expressly prohibit contractors from cutting and grinding tray segments inside what are essentially cleanroom environments. Prefabricated trays therefore not only save time during actual installation, but also the time it would otherwise take installers to walk the tray segments outside and back in each time they need to make a cut and grind it smooth, build a turn, or create a change in elevation.]

- Segregate low voltage and fiber optic cables from high voltage power lines. Use basket trays for the former, and heavy duty steel ladder and or aluminum trays for the latter. Run them in parallel side-by-side, or in separate tiers using threaded rods.

- Maintain a consistent cable jacket color coding standard for each type of cable in the tray; copper, fiber, telecommunication, Power over Ethernet (PoE), and high voltage power lines for easy identification, expansion, and repairs.

Related Article:

Data Center Structured Cabling: The Key to Efficient Data Center Design

Snake Tray Data Center Cable Tray Solutions

Snake Tray is a domestic manufacturer of cable tray systems for media and data as well as power distribution. All Snake Tray products are manufactured in the USA, made from 100% recycled steel, are prefabricated to eliminate waste, and totally reusable and reclaimable.

Snake Tray offers several types of prefabricated cable trays designed to ensure the proper spacing, turn radii, and consistent support of all cable types—copper, fiber, telecom, ethernet, and high voltage—in data centers from micro to hyperscale size.

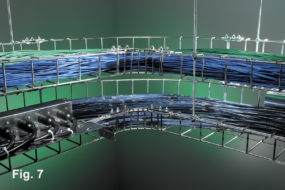

- 801 Series Mega Snake is designed to be mounted to walls, suspended from ceilings, or attached directly to the tops of server racks and cabinets. Strong yet flexible, Mega Snake is a functioning basket tray with the strength of a steel ladder. Made with 1/4″ round metal rods, it is better suited for today’s fiber-rich trunking systems than generic wire basket trays. Mega Snake is the only cable management system pre-manufactured in straight segments, turns, Ts, and crosses for a predictable, repeatable

solution. There is no on-site fabrication, cutting, or grinding required, speeding deployment while minimizing labor costs. Create any directional change in under five minutes and traverse open spaces without unsightly Unistrut trapezes (Fig. 5). Threaded rod attaches directly to the Mega Snake from above. Its built-in dual rod suspension system (Fig. 6) eliminates costly brackets and allows for easy attachment of auxiliary products like security cameras, patch panels, or to add entire traylayers to increase capacity or separate low from high voltage cables (Fig. 7). An easy to install splice kit quickly creates both a mechanical and a UL classified electrical bond between segments for the length of the run.

solution. There is no on-site fabrication, cutting, or grinding required, speeding deployment while minimizing labor costs. Create any directional change in under five minutes and traverse open spaces without unsightly Unistrut trapezes (Fig. 5). Threaded rod attaches directly to the Mega Snake from above. Its built-in dual rod suspension system (Fig. 6) eliminates costly brackets and allows for easy attachment of auxiliary products like security cameras, patch panels, or to add entire traylayers to increase capacity or separate low from high voltage cables (Fig. 7). An easy to install splice kit quickly creates both a mechanical and a UL classified electrical bond between segments for the length of the run.

- 301 Series Snake Canyon is the preeminent cable tray management solution for use underneath raised access floors. While most new data centers are being designed with their cable plants installed overhead, many facilities still use raised access flooring. This patented modular system is compatible with any brand or type of access floor, including stringerless floors. Snake Canyon fits under any 2′ x 2′ floor grid and offers integrated power distribution accessories to meet electrical and data center cabling needs in one solution (Fig. 8). Simply lift the floor panels and drop in Snake Canyon segments to

create a new cable pathway safely separated from other services running under the floor without impacting air flow. There’s no complicated hardware, special tools, or on-site fabrication required. Simple cam locks attach each segment to the floor grid or pedestals for stability and prevent tray movement. Cables are kept organized and out of sight, and the trays can be moved and reused as needed. Installation can be performed quickly by a small team or a single installer, minimizing labor costs.

create a new cable pathway safely separated from other services running under the floor without impacting air flow. There’s no complicated hardware, special tools, or on-site fabrication required. Simple cam locks attach each segment to the floor grid or pedestals for stability and prevent tray movement. Cables are kept organized and out of sight, and the trays can be moved and reused as needed. Installation can be performed quickly by a small team or a single installer, minimizing labor costs.

- A number of hand bendable trays including the 101 Series, 201 Series, 401 Series, 501 Series and 454 Series UniversalSnake Tray (Fig. 9) are available to easily route cables around obstructions or changes in elevation and are designed for

easy mounting and cable loading.

easy mounting and cable loading. - For hyperscale data centers with heavier cable loads, Snake Tray offers the 653 Series Aluminum Cable Tray (Fig. 11) andthe all-steel 610 Series Cable Runway (Fig. 12). The 653 Series is available in ladder, ventilated and non-ventilated trough types in a variety of widths and lengths. These lightweight sections are easy to install yet offer a high loading capacity to manage larger cable runs. Heavy duty brackets, fittings, and support accessories are available to create a customized, high capacity cable conveyance system for any environment. Aluminum cable trays are used to keep high voltage power and other non-communication cables separate from data lines. The 653 Series can be installed on rooftops, mounted to walls, suspended

from ceilings, attached to the top of cabinets, or bolted the floor.

from ceilings, attached to the top of cabinets, or bolted the floor.

The 610 Series is constructed of rectangular steel tubing to provide the strength to carry backbone and horizontal cables in telecommunications or equipment rooms, as well as cross-connects on racks and cabinets. The 610 Series supports loads of up to 130 lbs. per foot when the runway is supported every five feet. Snake Tray aluminum and steel cable trays feature easy-to-attach quick connect systems and are available in pre-manufactured turns and crosses to eliminate on-site fabrication.

Related Article(s):

Snake Tray’s 801 Series Mega Snake: Not Your Ordinary Wire Basket Tray

Reduce the Cost of Data Center Construction with Snake Tray

Snake Tray products offer predictability. Our prefabricated cable management systems allow for accurate cable pathway blueprinting and cost estimating by architects well before ground is broken. Once on the construction site, Snake Tray products are designed to install quickly, reduce labor and material costs, and significantly drive down the total cost of construction. Here’s how:

- Prefabricated. Snake Tray products are premanufactured for consistent quality and repeatability. Identical finished segments ensure rapid deployment and install with up to 50% less labor costs than traditional wire basket trays. Prefabricated cable trays also eliminate on-site cutting and grinding tasks, speeding installation while improving worker safety.

- Uniformity. Get predictable, repeatable results every time. Every fitting is the same no matter who installs it across all rows, floors, and entire locations.

- Fast installation. Link Snake Tray cable segments together in seconds and connect them to fittings—45° and 90° turns, Ts, 4-way crosses, and reducers—in under 5 minutes, all while maintaining proper support and bend radii for the length of the cable run. A splice kit maintains a continuous UL-approved mechanical/electrical bond throughout the system.

- Minimal hardware. The built-in dual-rail suspension system of the 801 Series Mega Snake eliminates the need for costly and time consuming brackets or center strut supports, further reducing installation costs. Built-in mounting rings on our hand-bendable trays simplify installation.

- Hand bendable. Products like the 101 Series, 201 Series, 401 Series, 501 Series and 454 Series Universal Snake Tray are made from lightweight steel that can be shaped by the installer without tools to route cables around obstructions or manage changes in elevation and direction in seconds.

- Zero waste. Use everything purchased for maximum ROI. No cutting means no scrap metal waste going to landfills, plus the hours not spent not making custom fittings on-site translates into more labor savings.

- Reusable, reclaimable, and expandable. Snake Tray products are made from 100% recycled steel and can be reused, moved, or expanded as needed.

Related Article(s):

Snake Tray: Innovating Solutions for The Not So Ordinary Problems

Video:

Your One-Stop Shop for Data Center Cable Management

Snake Tray is the premier provider of cable management solutions for any type of cable pathway…low or high voltage…overhead or under floor…copper or fiber. Snake Tray is the only manufacturer of prefabricated cable tray segments that speeds installation and reduces labor costs by up to 50%.

Snake Tray products meet data center demands for repeatability, fast deployment, and reliability at an affordable price. From hand-bendable conveyance to .25” steel wire basket trays to heavy duty aluminum and steel ladders, Snake Tray is your one-stop shop for data center cable management solutions. All are versatile, flexible, and reusable, and maintain the proper level of cable support, separation, and bend radius across your entire cable plant. Plus, Snake Tray products arrive at the job site in nested pallets to reduce shipping costs, packing material waste, and to make handling at the job site easier.

Are you curious to see how a Snake Tray-designed cable plant would look in your facility? Contact Snake Tray and put our design services to work for your next data center cabling project. We’ll help you save time and money. No cutting. No grinding. No kidding.

For a hardcopy version of this article, download our white paper, Data Center Construction: Living on The Edge.

For a hardcopy version of this article, download our white paper, Data Center Construction: Living on The Edge.