In the 28 years since Snake Tray was founded the company has grown into the industry leader in cable management. All Snake Tray products are designed around the principle of helping our customers lower their costs with innovative solutions that save on labor, take less time to install, and generally use less materials and hardware.

Today we offer a broad array of cable management solutions for a wide variety of industries and environments from data centers to hospitals, schools, mass transit systems, and financial services companies to utility-grade solar plants. In fact, Snake Tray invented modern solar cable management. It’s a cool story.

Back in 1996 we recognized that not every cabling job required a heavy-duty steel ladder or fixed wire mesh basket tray; it was overkill. Snake Tray brought to market a series of hand-bendable cable trays to route low voltage data and telecom lines around any obstacle without on-site fabrication. Installers can make a turn in 10 seconds to save on labor – no tools needed. Every tray includes built-in mounting hardware to speed installation and save even more on labor and material costs.

Back in 1996 we recognized that not every cabling job required a heavy-duty steel ladder or fixed wire mesh basket tray; it was overkill. Snake Tray brought to market a series of hand-bendable cable trays to route low voltage data and telecom lines around any obstacle without on-site fabrication. Installers can make a turn in 10 seconds to save on labor – no tools needed. Every tray includes built-in mounting hardware to speed installation and save even more on labor and material costs.

For high voltage cables and heavier cable loads, competitors offered wire basket trays and ladders that required expensive and labor-intensive fabrication of turns and fittings at the job site. As an alternative, Snake Tray launched a line of pre-manufactured wire mesh basket trays including turns, TEEs, and crosses. The 801 Series Mega Snake is as strong as a steel ladder yet is infinitely more versatile, lightweight, affordable, and requires no on-site cutting or grinding. It has a built-in suspension system, installs in minutes to reduce labor costs, and results in zero waste.

For high voltage cables and heavier cable loads, competitors offered wire basket trays and ladders that required expensive and labor-intensive fabrication of turns and fittings at the job site. As an alternative, Snake Tray launched a line of pre-manufactured wire mesh basket trays including turns, TEEs, and crosses. The 801 Series Mega Snake is as strong as a steel ladder yet is infinitely more versatile, lightweight, affordable, and requires no on-site cutting or grinding. It has a built-in suspension system, installs in minutes to reduce labor costs, and results in zero waste.

Long story short, architects, engineers, and electrical contractors quickly grasped the value of Snake Tray cable conveyance solutions and business boomed. After outgrowing a couple of leased locations, we built our own state-of-the-art manufacturing facility on Long Island, New York, and became one of the country’s premier domestic manufacturers of cable management systems with a reputation for innovating new labor-saving solutions.

As part of our corporate mission Snake Tray is committed to green design and manufacturing principles to minimize our impact on the environment. Our products are made from 100% recycled steel, minimize material waste, use less non-renewable resources, and nest together to lower fuel consumption and shipping costs. And that’s where our journey into solar begins.

Necessity is the mother of invention

We installed an array of solar panels on the factory roof to generate our own renewable energy to offset utility electrical consumption and reduce costs.

The roof, while open and flat, was not devoid of obstacles. It was a straightforward process to mount solar panels to the roof and installers easily worked around HVAC equipment, fans, vents, drains, pipes, etc. But it quickly became apparent that running all the solar panel string cables inside fixed conduit and fabricating odd-angled turns around those same obstacles was not a viable solution. And how else would the larger DC feeder cables traverse the roof, get down the side of the building, and into the inverters inside the plant – while maintaining NEC compliance?

A new solution was needed to organize and protect the DC string and feeder cables running from the solar panels to their termination points. As luck would have it, there was a cable management company operating under the roof!

Snake Tray engineers modified the design of our interior hand-bendable cable trays, and the 407 Series Solar Snake Tray was born. The 407 Series is the world’s only weatherproof, hand-bendable cable conveyance that quickly and securely carries DC circuitry from rooftop mounted solar panels to their terminations. Installers can change directions and elevations to easily navigate over, under, or around any obstruction simply by bending it into the desired position – no tools required. Built-in mounting rings allow for infinite mounting options with the flexibility to attach to any surface at any angle. As with our indoor cable trays, the sections are joined with a single connector bolt for a 15-second bonded attachment tray-to-tray.

Snake Tray engineers modified the design of our interior hand-bendable cable trays, and the 407 Series Solar Snake Tray was born. The 407 Series is the world’s only weatherproof, hand-bendable cable conveyance that quickly and securely carries DC circuitry from rooftop mounted solar panels to their terminations. Installers can change directions and elevations to easily navigate over, under, or around any obstruction simply by bending it into the desired position – no tools required. Built-in mounting rings allow for infinite mounting options with the flexibility to attach to any surface at any angle. As with our indoor cable trays, the sections are joined with a single connector bolt for a 15-second bonded attachment tray-to-tray.

But the 407 Series takes outdoor cable management to the next level: Unlike our indoor trays, the 407 Series features a patented “lobster trap” design to allow for effortless outdoor cable loading while maintaining proper bend radius and protecting cables from hurricane force winds of up to 120 mph. Made from galvanized ¼” steel wire, the 407 Series has a powder-coated finish to provide an extra layer of protection against outdoor elements and achieve a 25-year service lifetime.

We had a winner on our hands we and knew it. It was 2010 and critical mass was building for the rooftop solar industry. We reached out to the electrical contractor community that had embraced our indoor cable management solutions. They were seeking an alternative to conduit to expedite rooftop and car park solar jobs and make them more profitable. The 407 Series fit the bill as a single labor-saving solution could easily be applied to all types of outdoor structures. Suddenly Snake Tray had crossed over into another industry: solar cable management.

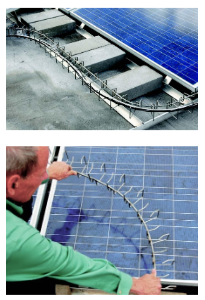

The 407 Series was a hit. Soon customers began asking for specialized solutions and accessories that Snake Tray engineers designed and transformed into repeatable products. One example is the Solar Panel Ice Guard, which protects pedestrians and vehicles from falling ice along walkways in locations with solar arrays overhead.

The 407 Series was a hit. Soon customers began asking for specialized solutions and accessories that Snake Tray engineers designed and transformed into repeatable products. One example is the Solar Panel Ice Guard, which protects pedestrians and vehicles from falling ice along walkways in locations with solar arrays overhead.

Today, Snake Tray is the “go-to” provider of solar cable management systems for all shapes and sizes of renewable energy projects. We are recognized as the world’s most innovative cable tray manufacturer with a growing catalog of solutions for all types of solar applications from utility grade solar plants, floating solar arrays, and covered parking structures, to battery energy storage systems and EV charging stations.

We applied the weatherproof powder-coated finish to the 801 Series to create the outdoor Solar Mega Snake. It manages the larger DC feeder cables that emerge from combiner boxes at the end of each row of rooftop solar panels and guides them safely down the exterior of the building to AC inverters. Today the Solar Mega Snake is also used to route power cables to EV charging stations.

We applied the weatherproof powder-coated finish to the 801 Series to create the outdoor Solar Mega Snake. It manages the larger DC feeder cables that emerge from combiner boxes at the end of each row of rooftop solar panels and guides them safely down the exterior of the building to AC inverters. Today the Solar Mega Snake is also used to route power cables to EV charging stations.

Moving from rooftop/covered parking to cabling utility-grade ground-mounted solar arrays presented different challenges and necessitated the development of new solutions. The traditional method of trenching high ampacity DC feeder cables was messy, expensive, and time consuming. Unforeseen obstacles under brownfields and weather conditions often delayed digging, and burying the cables meant reduced energy throughput, or derate, due to heat buildup. To compensate, solar utilities were installing much larger and more expensive cables. One sought us out to find an alternative solution.

That’s when Snake Tray invented the world’s first and only above ground free-air cable conveyance system. The Solar Snake Max leverages the pilings used to mount the solar panels and tensioned messenger wire to traverse any type of terrain. It eliminates trenching, the effects of derate, and allows the use of thinner cables to their full capacity. A system of brackets and polycarbonate cable separators, or clicks, maintain NEC-compliant cable spacing to allow the heat of friction to dissipate into the surrounding air. The Solar Snake Max takes less time and labor to install, increases energy production by up to 30-watt hours per meter over bundled/buried cables, and maintains total visibility to the cable plant for easier maintenance and repairs. Each run can hold up to 36 cables as large as 1250 Kcmil.

That’s when Snake Tray invented the world’s first and only above ground free-air cable conveyance system. The Solar Snake Max leverages the pilings used to mount the solar panels and tensioned messenger wire to traverse any type of terrain. It eliminates trenching, the effects of derate, and allows the use of thinner cables to their full capacity. A system of brackets and polycarbonate cable separators, or clicks, maintain NEC-compliant cable spacing to allow the heat of friction to dissipate into the surrounding air. The Solar Snake Max takes less time and labor to install, increases energy production by up to 30-watt hours per meter over bundled/buried cables, and maintains total visibility to the cable plant for easier maintenance and repairs. Each run can hold up to 36 cables as large as 1250 Kcmil.

As customers began using Solar Snake Max for new and expanding applications, we modified the original design to help our customers lower costs and reduce labor in all kinds of renewable energy projects.

As customers began using Solar Snake Max for new and expanding applications, we modified the original design to help our customers lower costs and reduce labor in all kinds of renewable energy projects.

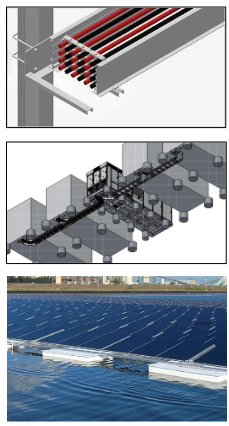

Today Snake Tray offers multiple iterations of the Solar Snake Max. The Solar Snake Max XL (top) uses a hard rail system for ground mounted runs, as does the Battery Energy Storage System (BESS) (middle) to store excess power in battery arrays. The Solar Snake Max XL for Water Installations (bottom) uses stainless steel rails on floating pontoons to transform utility plant water retention ponds into renewable energy sources. There’s even a Snake Max for AI Data Centers to meet the surging demand for energy to power and cool high performance computing assets. And then there’s our growing family of specialty messenger wire cable hangers, each inspired by a unique customer request. Tree hangers, single and double pocket hangers, squeeze-lock hangers, and torque tubes that safely move feeder cables as the solar panels track the path of the sun are just some of our more recent innovations – all centered on the principle of reducing installation time and labor.

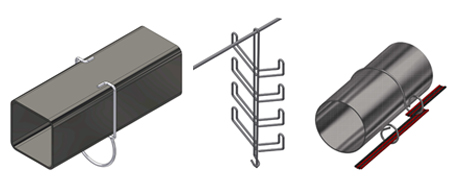

And then there’s our growing family of specialty messenger wire cable hangers, each inspired by a unique customer request. Tree hangers, single and double pocket hangers, squeeze-lock hangers, and torque tubes that safely move feeder cables as the solar panels track the path of the sun are just some of our more recent innovations – all centered on the principle of reducing installation time and labor.

Your next solution is right around the corner with Snake Tray

In 28 years, we’ve grown from one great idea into the most innovative U.S. producer of cable conveyance systems for a wide range of industries and applications, designing cost-effective solutions to problems never tackled before. In fact, somewhere across the globe, right now, the sun is shining on a Snake Tray solar installation.

Snake Tray offers a comprehensive selection of cable management products for indoor and outdoor applications, as well as a full line of under floor power distribution and enclosures – all designed to save on labor. Everything we make is sourced and produced domestically, insulating you from international supply chain headaches. Our engineers stand ready to help design custom solutions that cut costs and speed installation on your next cabling project. Visit us at www.Snaketray.com to learn more.