One of the hottest trends in renewable energy is building solar arrays over open air parking lots. Transforming open spaces into clean energy sources, offseting electricity bills while providing the amenities of shade, cooler vehicles, and protection from inclement weather to the people who park their cars underneath.

Solar-powered car parking arrays come in all shapes and sizes, typically erected on parking lots in excess of 100,000 square feet. Some arrays are sloped, others are inverted. Some are straight, others are curved. Some cover only the parking spaces, others cover driving aisles between the parking rows as well.

You’ll find them at airports, hospitals, train stations, business parks, schools, movie theaters, and shopping centers. Some are prefabricated, others are constructed using heavy duty trusses on site. Some are made using rigid panels, others use flexible lightweight sheets.

No matter the shape, size, or location, they all have one thing in common: the need for proper parking lot solar cable management.

There are four basic components to every solar array: the photovoltaic cells that capture sunlight and convert it into DC power, the racks and trusses onto which the panels are mounted, the inverters at the end of each row that convert the DC energy into usable AC power, and of course, the cables that tie everything together.

Engineers go to great lengths to ensure the highest quality solar panels and most efficient inverters are selected to complement their aesthetically-pleasing support structure design.

Here at Snake Tray, we’ve provided cable management systems for countless solar car parks. The problem is that very often cabling is an afterthought, left for last after the structure is complete. Engineers are primarily focused on the design and ROI.

Only after hundreds of connector cords are dangling from installed solar panels do contractors on the job realize there is no roadmap to connect the panels to DC power lines, no way to securely attach cables to the rack and run them to inverters at the end of each row, or even a place to mount the inverter.

That’s when the scrambling starts, jury-rigging cable supports, looking for ad hoc mounting solutions, and retrofitting terminal points.

A little forethought saves a lot of time

The average solar parking lot installation is a fraction of the size of utility-grade solar plants. There, tens of thousands of panels form arrays stretching hundreds of yards. They generate tremendous amperage and use higher gauge cables that demand a heavy duty cable management system..

Yet their girth and rigidity minimize sagging, so they actually need less support over long runs. NEC Code Article 690 calls for supports every four feet over the length of each high gauge cable run.

Conversely, parking lot solar arrays are usually designed in shorter rows. Shorter arrays generate less power and therefore use lower ampacity cables, usually 10 or 8 gauge. But these thinner, more pliable cables sag easily and must be supported every two feet according to NEC standards.

Sagging or dangling power DC cables are dangerous and out of spec. Besides contributing to an unprofessional look, loose cables are ripe for vandalism or rodent damage and could cause the project to fail inspection, resulting in additional time and expense to bring cabling up to code and delaying return on investment.

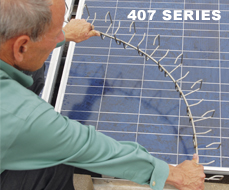

Snake Tray offers solutions specifically optimized for the job of managing low ampacity cables in solar parking lot structures. The 407 Series Solar Snake Tray is a lightweight, prefabricated cable tray that is as strong as steel yet easily bends by hand to go around any obstacle for unmatched mounting flexibility. The ideal solar car park cable management solution for car parks and ground mount installations, it features a “lobster trap” configuration to secure cables against winds up to 120 mph.

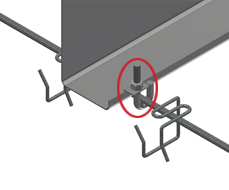

The Snake Hook (circled) allows for quick and easy attachment to any purlin-type structure. Available in multiple loading capacities, Solar Snake Tray offers built-in mounting rings and support arms spaced every 6” to exceed NEC support standards. Other accessories include inline tray connector bolts and cable waterfalls to make installation fast and easy.

For safety concerns, Snake Tray’s Solar Panel Ice Guard helps to aide in the prevention of ice and snow from falling off the surface of the solar panels. The system easily mounts to the frame of any solar panel and is designed to hold back frozen material up to the top edge of the guard, helping to protect pedestrians and vehicles from the dangers of falling ice. These patented solutions allow Snake Tray to come to the rescue when contractors call in a panic after rack construction is complete and they realize cable management was overlooked.

Snake Tray cable conveyance systems are infinitely versatile, allowing Snake Tray designers to easily reverse-engineer a solution to look like it was part of the original rack design. But by then time is of the essence, and overtime and rush charges quickly add up.

Snake Tray: Bringing predictability to unpredictable situations

Don’t allow parking lot solar cable management to be an afterthought. The truth is, there is no one-size-fits-all approach to building a solar parking lot or carport, but outcomes are better and costs are reduced when cable management is integrated into rack and truss design at the outset of the project. Having an interconnection plan up-front will allow for obstacles to be addressed and future upgrades or equipment add-ons like security cameras, Wi-Fi antennas, informational TV screens, traffic signals, lighting, and even electric vehicle charging stations to be built into the structure.

Contact Snake Tray at the inception of your next covered solar parking lot project. We’ll be happy to help you design an efficient cable management plan that will minimize materials and labor costs while ensuring cables are installed to code.

Snake Tray has revolutionized the data and power distribution market with cable management, power distribution systems and enclosures all designed to install quickly, reduce labor and material costs, and significantly drive down the total cost of construction. If you would like to learn more, visit us at snaketray.com . Our engineers and sales teams stand ready to help execute your next cabling project with maximum efficiency and profitability.