Storing surplus energy, whether derived from renewable sources, nuclear, or fossil fuels, has become a priority for many utilities and power generation companies.

For some, it’s about sustaining capacity during the transition from solar to turbines at sunset. For others, it’s about meeting daily peak period demands or continuing to provide service during an equipment failure, rolling blackouts, raging wildfires, or spikes in consumption.

Whatever the purpose of storing surplus energy, and regardless of the energy source, excess DC power is being stored in tractor-trailer-sized battery arrays during peak energy production hours, and then passed through an AC inverter and pumped out to the grid when needed.

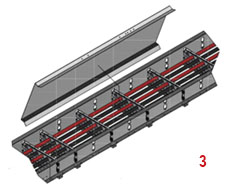

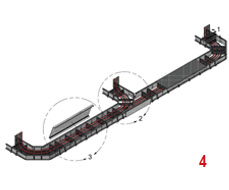

This graphic depicts a typical Battery Energy Storage System (BESS) with an AC inverter sandwiched between four large DC batteries and the cables that connect them. The four surrounding illustrations are exploded views of the BESS components featuring Snake Tray’s patented Solar Snake Max adapted for battery cable conveyance.

Snake Tray’s high ampacity trenchless cable management system employs a series of molded separators designed to carry up to 36 1,250 Kcmil cables in free-air, maximizing energy harvest and transfer rates for the highest possible return on investment.

The only one of its kind, Solar Snake Max eliminates cable bundling and the effects of derate that accompany heat build-up created by tightly bound high ampacity DC cables.

In the field, Solar Snake Max is supported by the posts and tensioned messenger wire running under the rows of solar panel arrays, gathering and carrying power to AC inverters.

In a BESS, the same principle of free-air cable conveyance is employed, but the cable separators are mounted to galvanized hard rails for stabilization and increased strength.

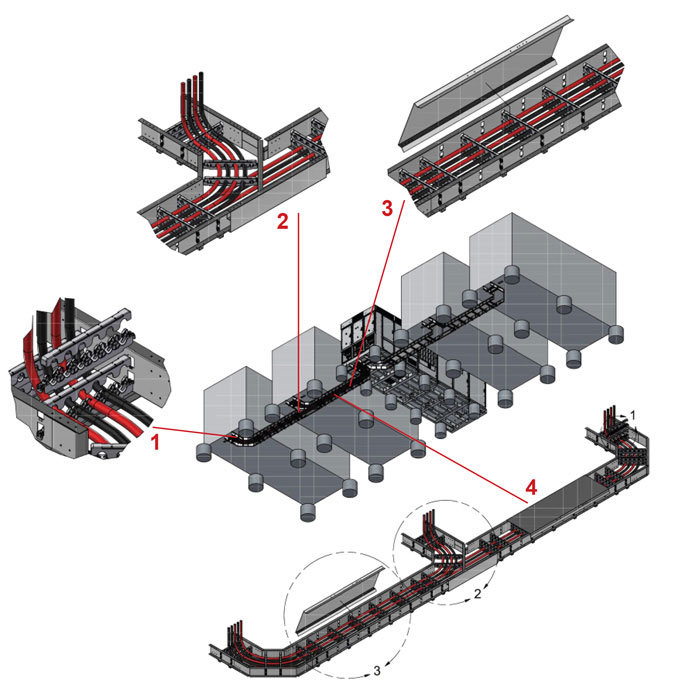

Figure 1 shows how the positive and negative cables are loaded, stacked, and held securely in place by separators, maintaining uniform separation necessary for heat dissipation. Up to 6 cables can be loaded in each layer up to 750 Kcmil, with a maximum of 6 layers – 4 across for 750 Kcmil – 1250 Kcmil.

Figure 1 shows how the positive and negative cables are loaded, stacked, and held securely in place by separators, maintaining uniform separation necessary for heat dissipation. Up to 6 cables can be loaded in each layer up to 750 Kcmil, with a maximum of 6 layers – 4 across for 750 Kcmil – 1250 Kcmil.

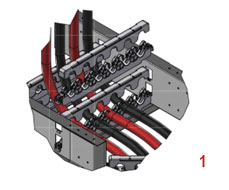

Figure 2 demonstrates other benefits of Snake Max: the ability to hold the proper bend radius as not to damage cables while maintaining uniform separation during changes in direction or elevation, and to easily integrate additional layers of cables running to and from multiple batteries into and out of the BESS.

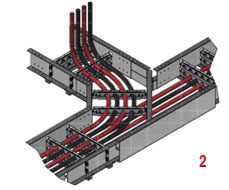

Figure 3 displays a section of straight tray that gets covered with a plate to protect exposed cables running between the batteries and/or the AC inverter. Sections under the batteries are not covered to allow the cables to exit the tray and connect to the battery terminals above.

Figure 4 is a break-away of the entire BESS, showing how the system allows for total visibility to all cables for easy loading, connection to battery terminals, periodic inspection, and replacement when necessary.

The same cables that feed excess power into the batteries are also used to push power out of the batteries, into the inverter and out onto the power grid. When that switch is flipped, a tremendous amount of heat is generated as current flows through the cables.

This is where the benefit of free air installation comes to the fore, allowing for maximum energy transfer between battery and inverter, and harvesting up to 8% more power than can be collected from a bundled cable system.

While borne from its roots in solar energy production, the adaption of the Snake Max for battery storage applications represents the innovation and dedication of Snake Tray engineers to meet any cable conveyance challenge regardless of how the power is generated.

Contact us at snaketray.com to learn how we can maximize the yield of your next battery energy storage system.