We’ve all seen how quickly a hotel can be erected. One day cement mixers arrive on a job site to pour a foundation and cast wall forms on the adjacent ground. Shortly after, cranes are brought in to lift the concrete slabs and support columns into their positions and voila! a new Marriott Courtyard, Best Western, Hampton Inn, or Holiday Inn Express appears in just a few weeks’ time.

This technique is called Tilt-Up Construction, and it is often cheaper, greener, and more efficient than other methods. It requires less wooden building materials, fewer skilled craftsmen, creates less waste, and dramatically speeds construction of the building envelope. However, tilt-up buildings are limited in terms of customization. Once poured, the concrete panels cannot be easily modified. As a result, Tilt-Up Construction best lends itself to modular, repeatable projects in which the layout of every building, floor, corridor, and room is nearly identical – a perfect fit for hotel chains.

This technique is called Tilt-Up Construction, and it is often cheaper, greener, and more efficient than other methods. It requires less wooden building materials, fewer skilled craftsmen, creates less waste, and dramatically speeds construction of the building envelope. However, tilt-up buildings are limited in terms of customization. Once poured, the concrete panels cannot be easily modified. As a result, Tilt-Up Construction best lends itself to modular, repeatable projects in which the layout of every building, floor, corridor, and room is nearly identical – a perfect fit for hotel chains.

Once the hotel framework is complete, contractors need simple solutions to speed the interior build-out, which includes running electrical cables as well as data and telecommunication lines and possibly climate control services into every room. This article explains how Snake Tray’s 701 Series MC (Metal Clad) Cable Management System is the perfect complement to the challenges of finishing hotels built using Tilt-Up Construction.

Modular, Prefabricated Components are the Key in Tilt-up Construction

It’s no accident that every guest room is arranged exactly the same. Bathrooms are located closest to main plumbing lines. Doors and windows are all uniform in size at identical positions with matching hardware. Twin lighting fixtures are wall-mounted on both sides of the built-in headboard. Every room has the same number of wall switches, power outlets, TV and telecommunication ports in the exact same position. This repeatability serves two purposes:

- 1. Allows builders to precisely estimate material needs to purchase the right quantities of identical supplies and components – much of it prefabricated – in bulk to lower costs and speed project completion.

- 2. Enables workers to quickly move from room to room, knowing exactly where to install everything from interior walls, flooring, window treatments, and plumbing fixtures down to the very last switch and outlet in every room, pulling components from a pre-packaged skid containing everything needed for each room.

When it comes to bringing electrical power into every guest room, one of the prefab components favored most by hotel builders is flexible MC conduit. Because the electrical configuration for each room is standardized, engineers know exactly how many circuits and what types of wires are needed. Those wires are bundled and inserted into a flexible metal clad jacket that protects and separates the wires dedicated to each room. Instead of tracing hundreds of individual wires down a hallway, electricians know that one MC cable carries all the lines needed to connect to the electrical distribution box in each room. Now the question becomes, how to efficiently route those MC cables to their destinations? Snake Tray has the answer.

Run MC Cables in Minutes with Snake Tray 701 Series

First, a couple of things to note about hotels built using the Tilt-Up Construction technique:

- 1. Floor heights are typically higher than in residential buildings putting the ceiling out of reach without ladders, but tolerances are very tight. There is minimal interstitial space between the horizontal slab and the dropped ceiling that will be installed beneath in hotel corridors. It’s a tight squeeze to fit and conceal all the electrical cabling plus fire suppression, audio/video, security, climate control, lighting, and other mechanical systems that run overhead in every hallway.

- 2. The underside of the concrete deck is a smooth, flat surface; there is no preexisting infrastructure, no notches to hang cable trays. Everything must be mounted directly to or hung from the slab. It is not possible to embed mechanical systems into each slab.

The 701 Series MC Cable Manager is the perfect solution for running MC cables overhead from the electrical closet at the end of the corridor to every guest room in the hallway. Here’s why:

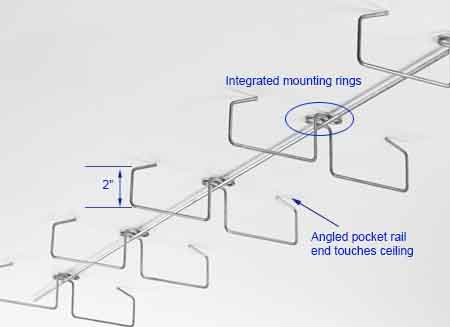

- Low Profile – Some versions are as shallow as 2” to easily fit in tight interstitial spaces.

- Built-in mounting rings – The steel spine attaches directly to the concrete slab (ceiling or wall) without brackets or accessories; just anchor the tray to the slab at 5-foot intervals with concrete lag bolts or other approved fasteners.

- Hand-bendable – Easily conform cable pathways to any corridor turn or around any obstacle (fire suppression system pipes and sprinklers, speakers, emergency exit signs, etc.) and make directional changes in seconds without tools. Installation is fast and does not require highly skilled labor.

- Unlimited length – The 701 Series comes in 10-foot sections that join together with a single connector bolt. Create cable pathways as long as needed without limits.

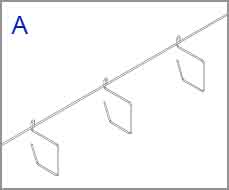

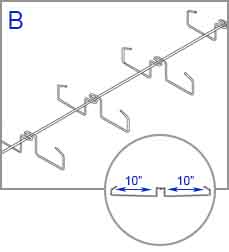

Versatile widths and configurations – Snake Tray offers a single pocket Wall Mount (A) version and a Double Pocket (B) version for overhead mounting. The Double Pocket is available in 5”, 8” and 10” pocket widths (B, inset) depending upon the capacity needed for each floor. Install it in the center of a corridor and neatly peel off MC cables to rooms on either side of the hallway.

Versatile widths and configurations – Snake Tray offers a single pocket Wall Mount (A) version and a Double Pocket (B) version for overhead mounting. The Double Pocket is available in 5”, 8” and 10” pocket widths (B, inset) depending upon the capacity needed for each floor. Install it in the center of a corridor and neatly peel off MC cables to rooms on either side of the hallway.

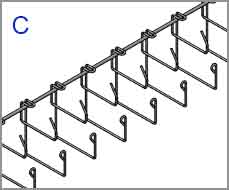

Usually, engineers prefer to keep power and data lines separate. For hotels running both power and data lines into every room, the Double Tier 701 Series (C) is a hand-bendable solution for carrying MC cables in the upper level and telecommunications and data in the lower level.

Usually, engineers prefer to keep power and data lines separate. For hotels running both power and data lines into every room, the Double Tier 701 Series (C) is a hand-bendable solution for carrying MC cables in the upper level and telecommunications and data in the lower level.- Easy MC cable installation – Once the tray is installed, MC cables are loaded into the 701 Series using a lightweight adjustable pole (D) to drop the cables into the tray from the ground. There’s no need for cable installers to step on a ladder, making it the safest and quickest solution for running MC cables!

Simple cable routing – Installers easily lift MC cables out of the tray at the desired position using the same telescoping pole as they move down the corridor to bring a MC cable into each room.

Simple cable routing – Installers easily lift MC cables out of the tray at the desired position using the same telescoping pole as they move down the corridor to bring a MC cable into each room. Secure – Look closely at the 701 Series and you’ll see that the end of each pocket rail is angled to contact the adjacent wall or ceiling. This creates an enclosed space from which cables cannot escape. When installing MC cables, the pole catches a section of MC cable in a collar (D, circled) which gives installers the leverage to push it past the rail, essentially snapping and locking MC cables into the tray in one step. This also applies to the upper level of the Double Tier 701 Series, whereas the lower tier is left open for loading data and low voltage cables.

Secure – Look closely at the 701 Series and you’ll see that the end of each pocket rail is angled to contact the adjacent wall or ceiling. This creates an enclosed space from which cables cannot escape. When installing MC cables, the pole catches a section of MC cable in a collar (D, circled) which gives installers the leverage to push it past the rail, essentially snapping and locking MC cables into the tray in one step. This also applies to the upper level of the Double Tier 701 Series, whereas the lower tier is left open for loading data and low voltage cables.

Raise Cabling Productivity with Snake Tray

Cabling hotels built using Tilt-Up Construction doesn’t have to be difficult or expensive. Not when you have the right tools for the job. With the 701 Series MC Snake Tray, electrical contractors can easily keep pace with the speed of hotel construction and bring the benefits of prefabrication, consistency, and reduced labor expenses to every project.

Elevate your productivity when you raise your next hotel with Snake Tray’s 701 Series MC Cable Management System, the perfect complement to Tilt-Up Construction. Contact us today to learn more.